It purifies oily mists, fumes and dust created by the machining of machine tools

The Coolibrì depurator is designed to efficiently and safely remove harmful emissions, such as oil mists, fumes and micro-dusts, generated during the machining of machine tools. The purification system has several stages of filtration:

- Metal mesh chip pre-filter: protects the centrifugal impeller from chips and impurities, also acting as a barrier for larger steam drops.

- ECF Forced Cyclone Effect Centrifugal Stage: Recover most airborne liquid droplets.

- Longe life stage: prolongs the life of the next pocket filter.

- Pocket filter stage: fibreglass filter with filter class ePM10 70%.

- Longe life + soundproofing stage: prolongs the life of the next HEPA filter and reduces the noise produced by the depurator.

- HEPA super filtration: blocks up to 99.95% of particles with a volume greater than 0.15 microns.

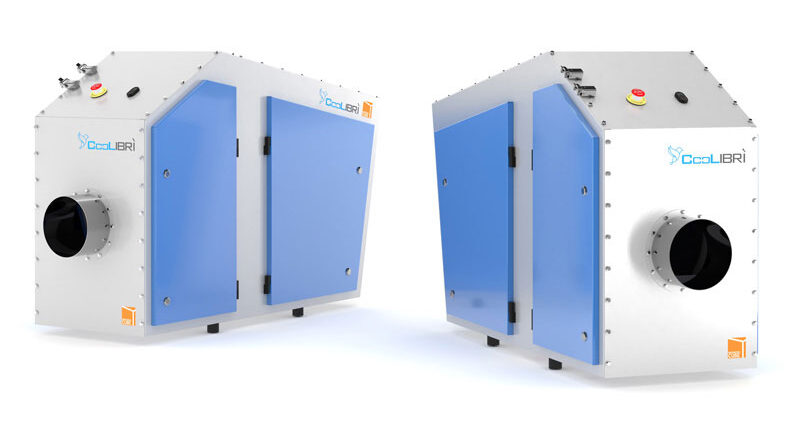

Coolibrì purifiers are made in a full-optional configuration and are designed to guarantee the health of workers. They are equipped with functions such as doors for maintenance on both sides, double inlet suction, pressure gauges for monitoring clogging and other options such as differentiated pressure gauges and booster systems to adjust the airflow.

The Coolibrì depurator is ideal for industrial environments and can be mounted on the head of chip evacuators. Protec Lab has designed Coolibrì with special attention to detail, providing a complete product with all the functions considered essential without requiring additional costs. The system contributes to the reduction of risk to workers’ health, regulatory compliance, improvement of indoor air quality and equipment durability.