Via Sacchini, 29 San Giovanni in Croce 26037 (CR)

Filtration systems

Home » Our industrial protection products » Filtration systems

The importance of filtration systems for lubricants in machine tools is decisive and that is why they can also be technologically different, to adequately respond to specific needs.

Filtration systems can be integrated or external to the machine tools. Lately, external systems are gaining more and more popularity for various reasons, including the optimisation of the use of space. In these cases, the synergistic collaboration between the machine tool manufacturer and La Protec begins from the design phase.

Booster+

Description

Booster+ consists of a filtration system, with a high-pressure tank and relaunch pump, all controlled by a PLC system with a touch screen. The Booster+ can be installed on board any machine tool and allows you to add up to 8 delivery lines.

Additional information

A high-pressure system, especially when working with materials such as aluminium and brass, requires an additional stage of filtration.

For this reason, the Booster+ picks up the coolant from the machine tank and, by filtering it, collects it in the internal tank. Not using in-line cartridge filters or hydrocyclones, minimising downtime and offers safe filtration. The liquid is then re-launched into tanks using a pump that distributes it over several outlets. The “continuous recirculation” function also allows you to filter the coolant in the tank of the machine tool, through an overflow discharge. All this is controlled by an advanced PLC capable of controlling countless parameters in real-time and communicating with the operator via a touchscreen interface.

BoosterOne

Description

High Pressure Filtration and Relaunch Control Unit.

BOOSTER-ONE is not only a high-pressure filtration and relaunch plant, with integrated PLC and Ethernet connection, but it is the opportunity for many customers to grow in efficiency while reducing costs.

Additional information

It contains all those functions essential for the treatment of high-efficiency lubricants, at the service of medium and large sizes such as transfers, multi-spindle lathes and machining centres all-in-one:

- filtration and superfiltration with self-cleaning systems

- thermoregulation

- Plug & Play

- preparation of all hydraulic connections.

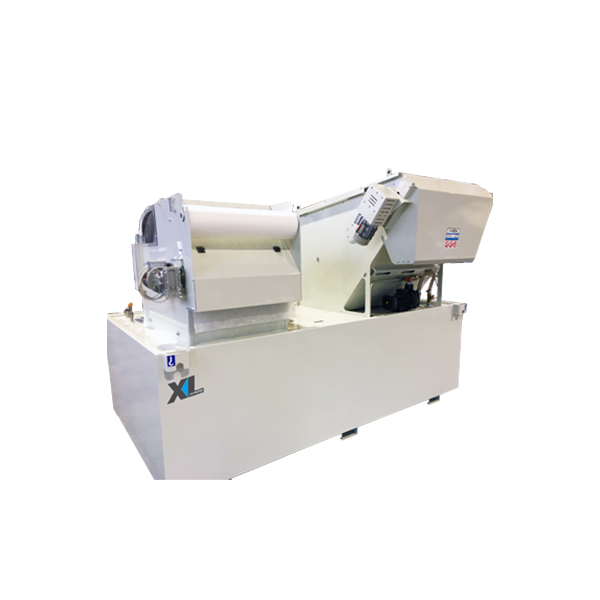

Filtration system consisting of a self-cleaning drum filter XL

Description

Complete ecosystem in stable equilibrium. The stability of the system is guaranteed by the balance between the various components resulting from La Protec research and experience, which these products represent the synthesis.

Additional information

It is possible to configure your XL system from 300 to 400 or 500 L/min nominal with different tank capacities: from 1000 L and 2000 L of standard size up to 3000 L on extra machining.

Paper Filtration System

Description

A machine that allows, by simple gravity, through a non-woven fabric, the filtration of refrigerants with a very high degree of purification. The filter media automatically renews once clogged.

Additional information

There are several applications of this particular filter with a filtration degree of 50/25/10 microns: grinders, sharpeners, lappers, working centres, and transfers. Flow rates range from 40L/1’ to 500L/1’. It can also run off a battery.

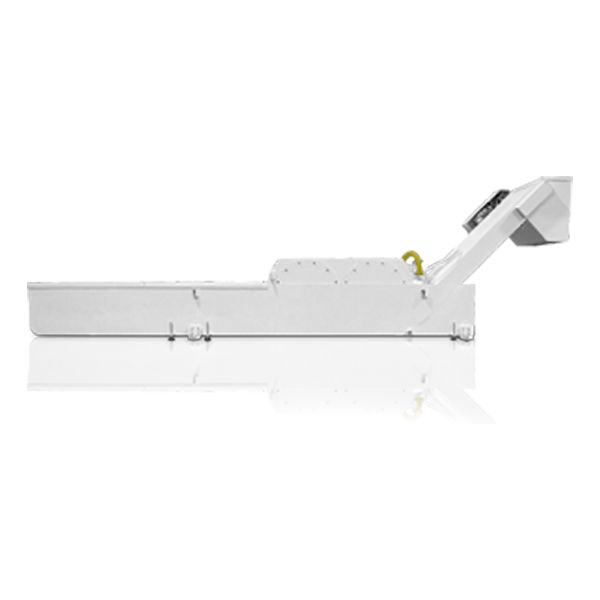

Conveyor with self-cleaning filter

Description

Dragging conveyors with self-cleaning filters are particularly suitable for applications with small chips, for example, produced by the processing of brass or cast iron.

Additional information

The self-cleaning drum filter with easy access for maintenance involves filtration degrees ranging from 500 microns to 200 microns with a flow rate ranging from 200 L/1’ to 1000 L/1’.

Sign up for the newsletter